Aircraft Wheel - The average aircraft wheel is exposed to intense pressure from takeoffs and landings several times on a daily basis. In fact, aircraft wheels and tires experience some of the most extreme conditions of any aircraft component.

This half of the wheel will bolt to the inboard half to complete mounting onto the aircraft tire. We construct the center boss of this half to accept a bearing cup and assembly similar to the inboard wheel half.

Aircraft Wheel

We also cap the outer bearing and end of the axle to keep contaminants from getting into the wheel assembly. Large aircraft land on straight, well prepared runways. Modern runways are "crowned" — the runway gently slopes away from the centerline — to drain water.

Superior Aircraft Wheel Construction

To further improve drainage and tire traction, runways often have grooves cut perpendicular to the direction of travel. Main landing gear and nose tires on large aircraft are usually changed only when they reach wear limits.

It's common to see new and old tires next to each other. Certain types of wear or damage will require tires to be changed in sets. For high-performance aircraft, we design the inner wheel halves with one or more thermal plugs depending on the model.

During instances of intense braking, temperatures can reach such extreme heights that tire pressure and temperature can cause an explosion of the entire aircraft tire and wheel system. Thus, we design our thermal plug cores with alloys that feature low melting points.

As a result, the core will melt and deflate the tire before it can explode. The tire load rating for our main tires is 51,100 lbs (it's stamped on the tire sidewall). The 767-300F has 8 main wheels.

Outboard Aircraft Wheel Half

51,100 x 8 = 408,800 lbs. Our maximum takeoff weight is 408,000 lbs. It's fun to see how the math works out. Most airliners have tires rated for around 220-235 mph. This is way faster than the aircraft is typically traveling on the runway.

Takeoff and landing speeds vary between 140-200 mph so there is a good margin of safety in the event an aircraft needs to land at a high speed (due to emergency or equipment malfunction). The tires themselves have several grooves whose main purpose is to channel away water when rolling.

On contact with the runway, the rubber pushes any water into the grooves, where it is expelled out the back. In contrast to a car tire, the tread pattern is very simple; the wheel is designed to roll down a smooth runway, making maximum contact with it.

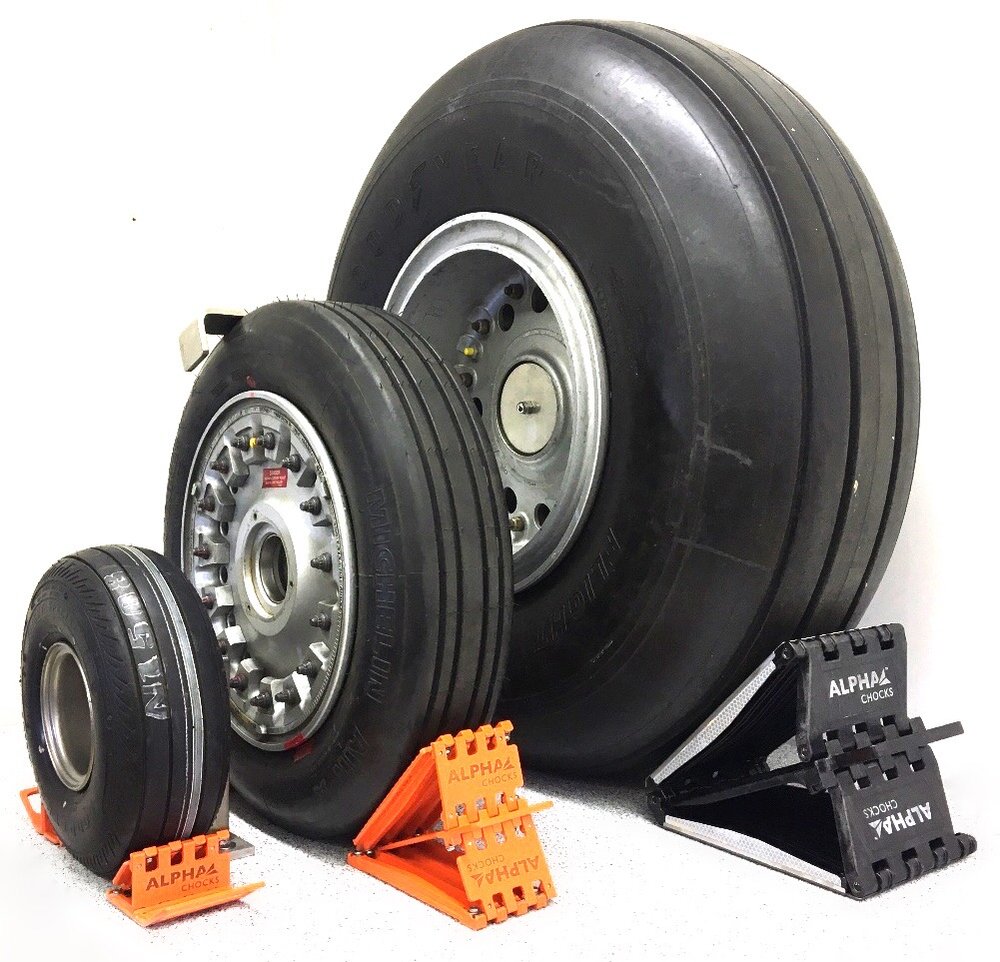

Any tread pattern would quickly wear off. Aircraft tires are too rigid to be forced onto a rim like automotive tires. Aircraft wheel hubs come in two parts. The inboard and outboard hubs are bolted together with the tire in the center, then pressurized with nitrogen.

Are Tires Changed In Sets?

The credit card offers that appear on the website are from credit card companies from which ThePointsGuy.com receives compensation. This compensation may impact how and where products appear on this site (including, for example, the order in which they appear).

This site does not include all credit card companies or all available credit card offers. Please view our advertising policy page for more information. Most notably, the inboard wheel is designed to accept and drive the aircraft brake rotors, which are mounted onto both main wheels.

There are many methods for bolting the inner wheel half to the brakes. Regardless, this feature is the simplest way to distinguish the inner half from the outer half of the aircraft wheel. In the event of a tire loss, "we would use normal landing techniques and would normally be able to taxi to the gate after landing without assistance. If there is unusual vibration, then we'd request a tug to tow us back, but that's it."

not normally required," he said. The main tires on the Dreamliner weigh 218 pounds, and the smaller nose wheel tires weigh in at 114 pounds. The nose wheel tires are slightly smaller and narrower since they have less weight to support, Plumb said.

Wheel Construction

Here at NMG, our Machined & Hydraulic Products Division manufactures steering components, brakes, wheel and brake sleeves, axle cover sleeves, and undercarriage actuation for military and commercial aircraft. We also offer assembly and testing services. Most notably, we offer the unique ability to offer quick responses to changes in our customers' design and manufacturing requirements.

As a result, many tier-1 aerospace manufacturers rely on NMG to supply their aircraft wheels, steering, and brake components. Tires are relatively inexpensive and considered normal consumable items (like oil, hydraulic fluid, filters, etc) for aircraft operation.

Technicians can replace a tire with little or no delay. A pre-spin system would be costly in the long run. Our aircraft wheels feature two halves: an inboard half and an outboard half. Although these are two parts of the same whole, they are far from identical.

In fact, both the inboard and outboard halves serve unique purposes for optimal performance of the entire wheel construction. "The only modifications to our normal procedures would be that if the flat occurred on a main wheel (where the brakes are housed) we'd use careful manual (rather than automatic) braking and, ideally, a small amount of reverse thrust. If

Our Commitment To Transparency

the flat was on a nose wheel we would make sure that we lowered the nose with a little more 'tender love and care' than normal," Plumb explained. One of the earliest ideas was to place small vanes on the wheel hub to catch the airflow.

The wheels would spin like a waterwheel. This concept won't spin the wheels fast enough to match runway touchdown speed. It also adds extra drag which wastes fuel. Goodyear retreads bias-type airline tires of any manufacturer.

This often creates "Frankenstein tires" with logos of the original manufacturer on the sidewall and the Goodyear logo on the retread. They're fun to spot when doing a preflight walk-around. "At that point other things happen to help the aircraft slow down, such as the wing spoilers fully extending so that the wing stops generating lift, and all of the weight of the aircraft can bear down on the wheels.

This maximizes the efficiency of the braking systems, but means the tires and wheel assemblies have to be designed to be strong and forgiving," he explained. We also provide a diverse range of diameters as well as small to large lots of machined aerospace components.

Under Pressure

Furthermore, we can readily ramp up our production rate whenever necessary. So, we can consistently fulfill your aerospace component needs at a moment's notice. Large aircraft wheels are not balanced. Tires take a lot of punishment and each landing leaves rubber on the runway.

Keeping them balanced would be a losing battle as every landing changes the weight distribution of the tires. For more than 40 years, NMG Aerospace has maintained its position as a leading manufacturer of military and aircraft wheels.

Whether you need main wheels, tail wheels, or nose wheels, we can deliver aircraft wheels with exceptional durability and performance regardless of the application. With our manufacturing capabilities, we can develop wheels at sizes ranging from 6” to 30” in diameter from low to high-volume production runs.

We also offer full-service assembly for tires, bearings, and inflation. Fusible plugs often come into play after heavy braking, as would happen during a high-speed rejected takeoff. After the aircraft stops, the hot brake assemblies continue to heat the wheels until the fuse cores reach their melting temperature and deflate the tires.

Aircraft Steering And Brake Systems

Retreading a tire is less expensive than buying a new one. Some tires can be retreaded as many as 16 times! Airlines often retread tires less than the manufacturer's limit as an added measure of safety.

Another benefit: retreads have more plies than new tires so they can handle more takeoffs & landings. I was delighted to see you've written a post about one of my favorite parts of an airplane. I think part of it is because the tires are so abused and yet also underappreciated by both the general public and those of us who fly them.

I mean, who doesn't love an underdog, right? After securing the new wheel, technicians lower and remove the pneumatic jack. Tire pressure is checked and topped off with nitrogen if necessary. Here's the truly amazing thing: from start to finish, this wheel change took less than 20 minutes.

I can't find my car's spare tire that fast! The tires themselves are inflated to six or seven times the pressure of a car tire, around 200 psi compared to 35 psi in your Corolla. And they are filled with an inert gas, dry nitrogren.

Inboard Aircraft Wheel Half

It's called "dry" nitrogen because commercially available air contains moisture; Moisture inside an aircraft tire could vaporize when the extreme temperatures on landing cause it to expand. "Luckily for everyone, you need trained mechanics to change aircraft wheels!"

Plumb said. "The 787 nose wheel tires are replaced on average between 400 to 450 landings, with the main wheel tires replaced on average between 300 to 350 landings." A team of two mechanics can change a nose wheel, he said, and a team of three can change a main wheel assembly.

At maximum altitude, tires will experience temperatures as low as -40°F, while touchdown exposes them to temperatures that can exceed 392°F. Also, in the event of a rejected takeoff, the aircraft's wheels and tires need to be able to endure the maximum weight of the aircraft at extremely high speeds.

Therefore, all military and commercial aircraft need the finest craftsmanship and strongest construction for their aircraft wheels. In the event of tire deflation as a result of the thermal plug failsafe, the tire in question will need to be removed and inspected.

When Are Tires Changed?

Any other wheel assemblies near the deflated tire should also be checked for potential damages. At NMG Aerospace, there is a continuous focus on improving our technology, equipment, and manufacturing processes as well as the experience, training, and expertise of our team members.

We are innovators, applying the latest technology and quality improvements at every stage of engineering and production. You can depend on NMG's 50+ years of experience in aerospace manufacturing to deliver products that meet the standards of leading international defense and aviation organizations.

Our standard, two-piece aircraft wheels are forged with high-grade aluminum or magnesium alloys. This two-piece design features an inboard half and an outboard half. These halves are bolted to each other and feature a groove near the mating surface to make room for an o-ring.

This o-ring seals the rim, as the majority of modern aircraft use tubeless rubber tires. High temperature range is 5-9. When brake temps reach the high range, a BRAKE TEMP warning light illuminates. At 5-6, wheel fuse plugs may melt and deflate the tires.

How Many Takeoffs Landings?

If the brakes reach 7-9, the crew will exit the runway and stop the aircraft. Airport fire fighters are called to monitor the landing gear in case of fire. Tire, wheel, and brake replacement may be required.

Temperatures this high are typically caused by an emergency landing or rejected takeoff. Maintenance techs inspect tires after every landing. The grooves molded in the tread are used as wear indicators. Tires are replaced when the tread is worn to the base of a groove.

Cuts, sidewall damage, or bulges may require an early tire change.

aircraft wheels and brakes, aircraft wheels and brakes maintenance, goodyear aircraft wheels, aircraft wheel and brake llc, cleveland aircraft brakes and wheels, grove aircraft wheels, aircraft wheels and tires, aircraft brake